- Home

- Low Voltage Inverters

- Application of VEICHI AC300 in Synchronous Transmission Control System

Overview

With the continuous development of society and the rapid advancement of science and technology, more and more mechanical work situations need to be controlled synchronously. In order to improve production efficiency, modern production and processing processes are automated and continuous production. Therefore, the reliability, economy, speed ratio and synchronization performance of the drive motor are put forward higher requirements. At present, there are common synchronous control in textile, machinery, chemical fiber, steel, electric power, paper, food, chemical, petroleum, wood and other industries. VEICHI inverter has relevant successful application cases in these industries. The following are some simple related applications.

Application of AC300 Inverter in Synchronous Control of Forming Machine

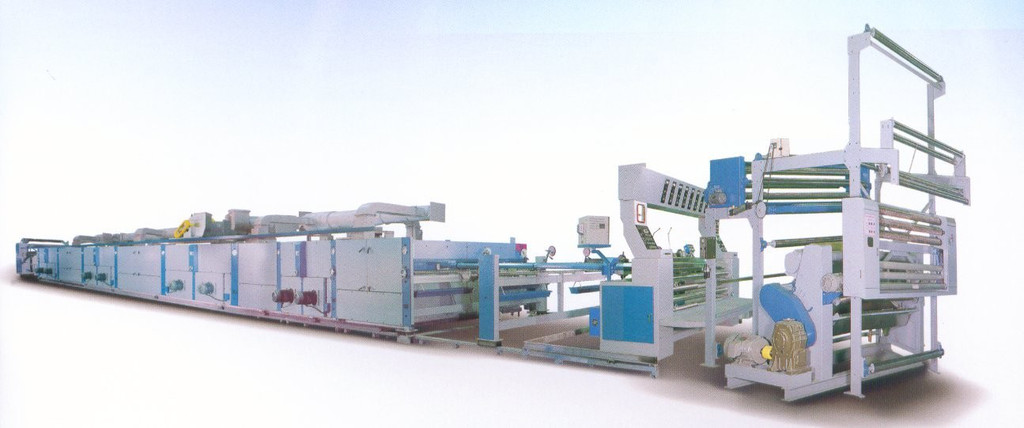

1. The working principle of the setting machine

The unshaped cloth is fed into the machine by the flat stripper, and the machine automatically attaches the two ends of the cloth to the needle board. Both ends of the needle board enter the oven with the mechanical running step, the oven is heated by electric, and the fan is blown. After several consecutive constant temperature ovens of different temperature sections, after entering the tail end, after cooling and static electricity, the swing falls into the cloth, and the cloth is crisp and beautiful.

2. The composition of the shaping machine and the role of each part

The shaping machine is mainly composed of five parts: a feeding part, a weft feeder, a chain, an oven, and a cloth distributing device.

(1) Loading part

The structure is relatively simple, consisting of a trough and a roll. The cloth enters the trough, carries the chemical material, and then presses the excess chemical material through the roll to clean it. Therefore, the chemical material on the cloth is very uniform, which is a prerequisite for obtaining high quality styling cloth. It should be noted here that it is necessary to always pay attention to whether the pressure on the left and right sides of the roll is consistent. Otherwise, the side with less pressure will be loaded more, while the side with higher pressure will have less material, and the cloth will have inconsistent quality problems.

(2) Weft feeder

The weft aligner on the fixed machine is the Mahlo RFMC94H photoelectric weft aligner. There are four sets of sensors on the Mahlo photoelectric weft aligner. Each sensor consists of two parts, illuminating and sensitizing. The action part adopts a hydraulic system. When the signal of the slanting size is transmitted back to the control board, the control board will issue a command to drive the hydraulic system to adjust the angle of the curved roller or the straight roller to correct the weft. Specifically: when the center of the cloth is different from the two sides, the curved roller will move; when there is a difference between the left and the right, the straight roller will move.

Weft feeder

(3) Chain part

The tenter on the setting machine is produced by the chain. The chain of the setting machine is driven by the high-power motor near the falling cloth. The chain is equipped with a needle plate. When the cloth enters the chain, the cloth is pressed by the brush wheel on the pressing wheel. On the small needle on the board, the cloth can enter the oven under the drive of two columns of chains. This type of machine's purlins is different from other stereotypes. It can control the pulling of each needle to achieve good results. Some setting machines can't adjust the needles. In a rectangular or trapezoidal shape.

Chain part

(4) Oven body

The setting machine has eight sets of ovens, and the air is continuously sprayed on the cloth surface by the fine holes on the star-shaped jet frame under the action of the circulating fan. After the hot air contacts the wet cloth, the temperature drops and the humidity rises, and is discharged from the large hole in the star-shaped jet frame, passes through the filter net, and then is continuously circulated by the heat exchanger. The heat exchanger is located below the filter and the hot coal is hot oil. The heat exchanger has many thin fins for efficient heat exchange.

(5) Falling cloth and winding device

The setting machine can be arranged in two ways, depending on the production needs, in the form of a cloth or a roll. Both modes are driven by the motor to drive the chain. When the cloth is used to take out the cloth, the tension stability of the cloth is required to be high, and the cloth needs to pass through a tension adjusting guide roller controlled by the air cylinder. In the case of a cloth-type drop cloth, the cloth does not need to pass through the tension adjusting roller to change through a fixed guide.

Falling cloth and winding device

3. The setting machine can be arranged in two ways, depending on the production needs, in the form of a cloth or a roll. Both modes are driven by the motor to drive the chain. When the cloth is used to take out the cloth, the tension stability of the cloth is required to be high, and the cloth needs to pass through a tension adjusting guide roller controlled by the air cylinder. In the case of a cloth-type drop cloth, the cloth does not need to pass through the tension adjusting roller to change through a fixed guide.

In the case of a cloth-type drop cloth, the cloth does not need to pass through the tension adjusting roller to change through a fixed guide

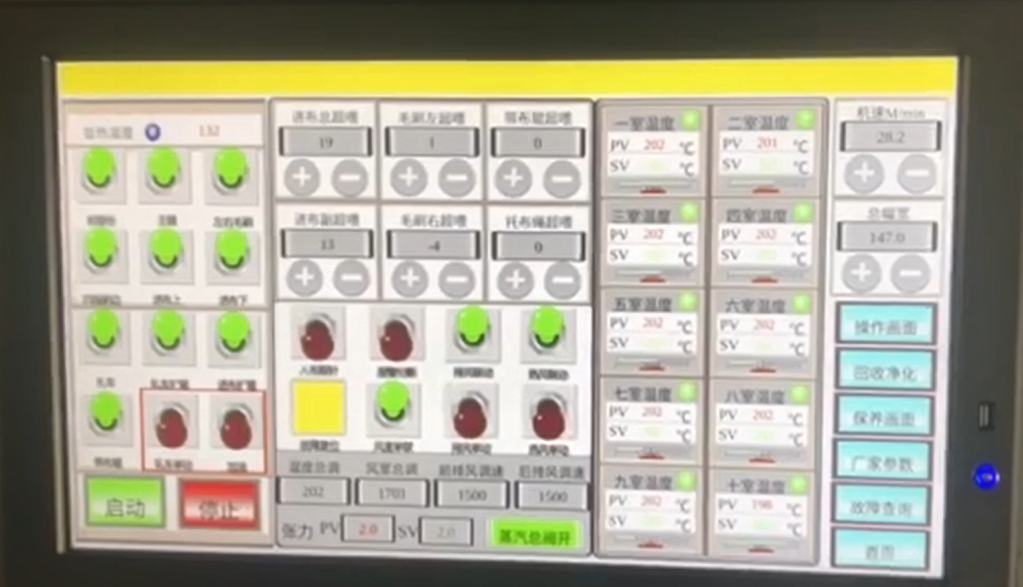

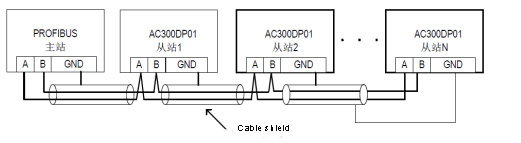

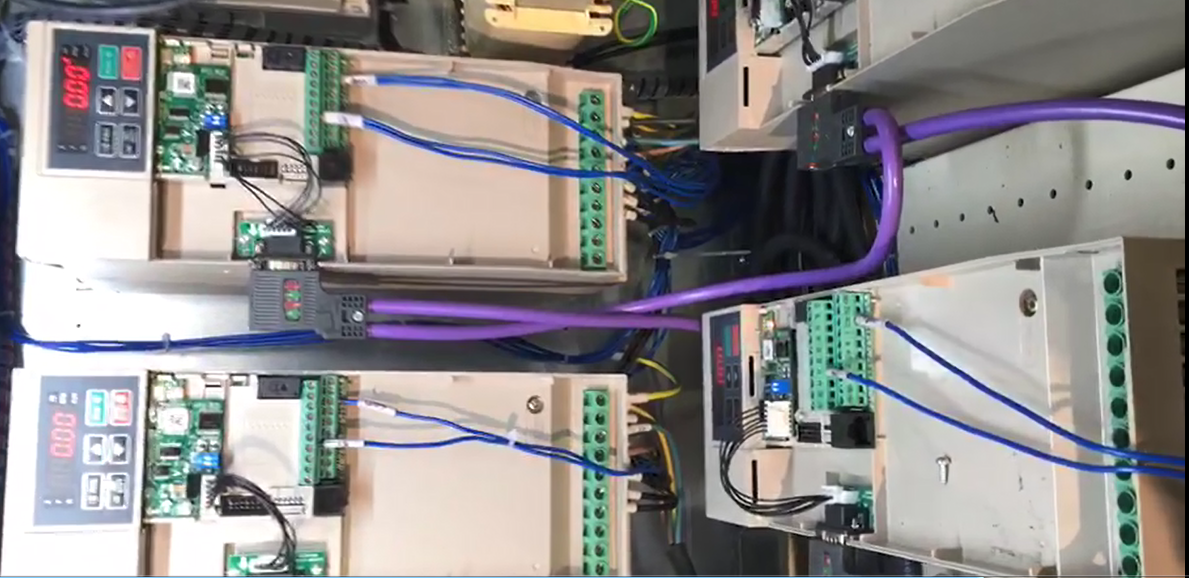

4. In order to ensure the synchronization of each motor, determine the mechanical transmission ratio, plan each transmission association, the inverter in the form of a slave and the host computer through the communication mode (MODBUS 485 or PROFIBUS DP), and send the run command and frequency given. The excellent response capability of our AC300 inverter can quickly respond to the command given by the host computer, thus ensuring the synchronization of the machine.

AC300 inverters

Parameter setting (MODBUS 485): Parameter setting is simple, fast and convenient!

| Function number and setting value | Function name | Function number and setting value | Function name |

| F00.02=2 | Run command given 485 | F00.03=6 | Frequency given 485 |

| F13.00=1 | Slave selection | F13.01 | 485 communication address |

| F13.02 | Communication baud rate | F13.03 | MODBUS data format |

Parameter setting (PROFIBUS DP): You can use the default PZD1 by configuring our GSD file in DP!

| Function number and setting value | Function name | Function number and setting value | Function name |

| F00.02=2 | Run command given | F00.03=6 | Frequency given |

| F13.00=1 | Slave selection | F13.27 | DP communication address |

| The primary station sends data to the PZD area | ||

| Inverter command | Inverter target frequency | Inverter function parameters change in real time |

| PZD1 | PZD2 | PZD3~PZD10 |

| nverter response data PZD area | ||

| Inverter status | frequency inverter running frequency | Real-time reading of inverter function parameter values |

| PZD1 | PZD2 | PZD3~PZD10 |

Parameter setting is simple, fast and convenient

Application of AC300 Inverter in Synchronous Control of Composite Machine

1. Overview

TPU composite is a composite material of TPU film composite on various fabrics, combining the characteristics of the two to obtain a new fabric. TPU can be formed into a film by flowing, blown film, calendering or coating. It has the advantages of good elasticity, toughness, wear resistance, good cold resistance, environmental protection and non-toxicity. There are many small factories in China, most of which are TPU films purchased from outside film factories, and they only complete the process of gluing. After the post-paste process, TPU film should be added with high temperature and high pressure again. If the process is improperly controlled, it will cause damage to the film, even small holes. The frequency conversion can control the speed of the motor, so that it can be slow to the high speed in the production process when the glue is applied. When the film is uneven in a certain link, the terminal can be controlled to accelerate and decelerate to achieve the speed of the motor and improve the quality and efficiency of the TPU composite product.

2. The complete set of equipment and working principle on the glue point machine

The whole set of glue point machine is generally composed of 10 sets of control motors, main body, gluing, curling, opening, conveying, water cooling, traction, silicon opening 1, silicon opening 2, and film laying. By controlling the start on the control terminal, the total adjustment is controlled to control the speed of the entire motor. When a film is uneven in a certain section, it can be adjusted by the trimming potentiometer corresponding to the motor, so that the frequency of the main machine, the glue, the opening, the conveying, and the opening speed of the silicone opening 1 and 2 are consistent, and finally the synchronous production of the product is realized.

Application of AC300 Inverter in Synchronous Control of Composite Machine 1

Application of AC300 Inverter in Synchronous Control of Composite Machine 2

Application of AC300 Inverter in Synchronous Control of Composite Machine 3

3. Functions implemented on the glue point machine

The function of the glue point machine on the TPU compound machine: the whole set of motors can be synchronized, and the multi-speed is realized, the operation is stable, and the tension of each film should be consistent. The following are the characteristics of a composite machine:

(1) Special high-efficiency drying oven to improve drying efficiency and reduce energy consumption;

(2) Using an anilox roller gluing method, evenly coating;

(3) Realize precise synchronous control and multi-point control, easy to operate and maintain;

(4) Individual fine-tuning and total fine-tuning can achieve acceleration and deceleration;

Host parameter settings:

| Function number and setting value | Function name |

| F00.00=0 or 1 | To be consistent with the slave |

| F00.02=1 | Terminal control |

| F00.03=2 | (AI1 given) main potentiometer + trimmer potentiometer |

| F00.09=50 | Maximum frequency |

| F00.11=50 | Upper limit frequency |

| F00.14 | Acceleration time (mainframe and slave are consistent) |

| F00.15 | Deceleration time (main unit and slave are consistent) |

| F01.16 | Acceleration and deceleration mode (main unit, slave machine consistent) |

| F02.00=1 | Forward running |

| F13.00=1 | Set as host |

| F13.09=0031 | The host sends the slave output frequency and running command, and can set the send run command according to the actual situation. |

Slave parameter setting:

| Function number and setting value | Function name |

| F00.00=0 or 1 | To be consistent with the host |

| F00.02=2 | Communication control |

| F00.03=6 | Communication given |

| F00.04=2 | (AI1 given) bipolar potentiometer for fine-tuning the frequency. If the speed of the slave and the host are inconsistent during the speed regulation, the potentiometer can be adjusted. |

| F00.05=1 | Set channel A as the reference source, channel B set frequency = channel B frequency reference source × channel A set frequency absolute value / maximum frequency), because it is in fine tuning mode, so F00.05 is recommended to be set to 1, Not set to 0 |

| F00.06=2 | Frequency combination mode channel A+ channel B |

| F00.09=50 | Maximum frequency |

| F00.11=50 | Upper limit frequency |

| F00.14 | Acceleration time (mainframe and slave are consistent) |

| F00.15 | Deceleration time (main unit and slave are consistent) |

| F01.16 | Acceleration and deceleration mode (main unit, slave machine consistent) |

| F13.00=0 | Set to slave |

| F13.00=1, 2, 3, 4...... | Set the slave address according to the number of slaves |

The AC300 inverter of our company has many applications in the synchronous transmission field, achieving synchronization and proportional linkage between multiple motors, and has the advantages of high cost performance, high control precision, fast performance response, simple wiring and convenient operation. In the industrial control industry to get a good reputation. In the future, we will provide better synchronous transmission solutions, and we will plow in the synchronous transmission application to give our customers a better sense of use.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message