- Home > Product > Industry-specific Drive > Pump Drive & Motor > GS10 Mini Pump Drive

GS10 Mini Pump Drive

- Motor protection function

- Perfectly drive a variety of pump motors

- Network Port Extension Interface

- Multiple pump control

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

GS10 Mini Pump Drive

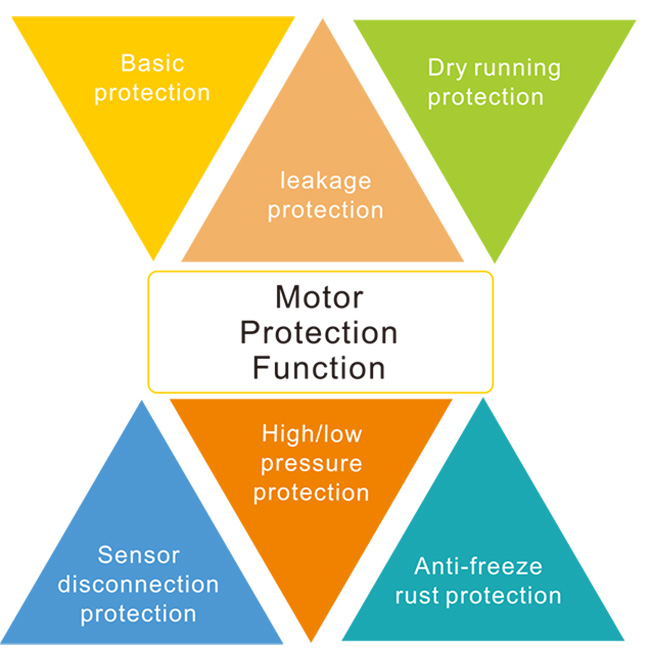

Motor protection function

Multiple inverter basic protection functions;Water pump exclusive protection function(water shortage protection,high and low pressure protection,leakage protection,anti-freeze embroidery protection,sensor disconnection protection).

Perfectly drive a variety of pump motors

Perfectly drive a variety of water pump motors such as asynchronous, permanent magnet synchronous, synchronous reluctance, etc.

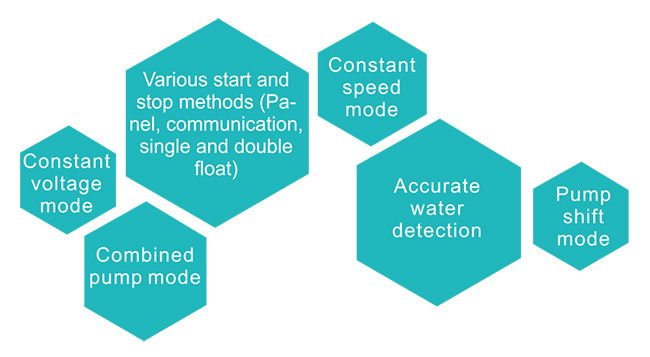

Multiple water supply functions

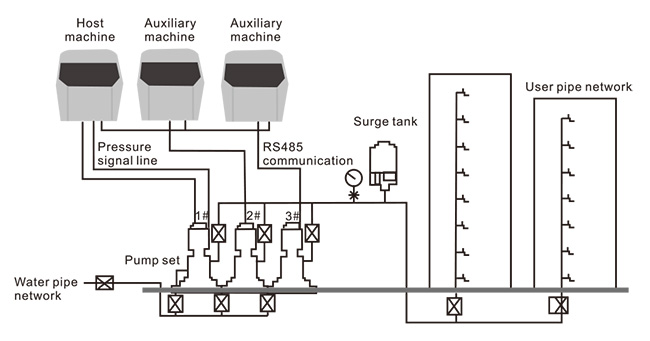

Multiple pump control

1. The pressure of the pipe network is detected by the host and sent to the auxiliary machine. When the pressure is not enough, the auxiliary machine starts and runs according to the set frequency.and the main machine performs constant pressure PID adjustment.

2. The main and auxiliary machines altermately run in sequence at regular intervals to realize the uniform use of the water pump and extend the life of the water pump.

Network Port Extension Interface

The network model supports RS485(standard), which could be directly extended through the network port. Customers only need to make a network cable connection, convenient and beautiful.

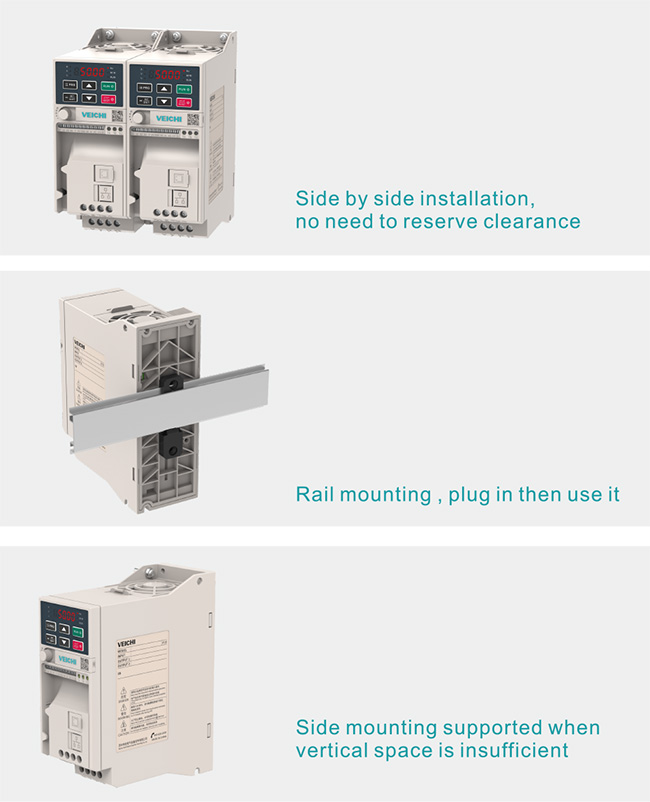

Installation Methods

Support penetration installation (wall installation,embedded installation):Adapt to various installation environments.

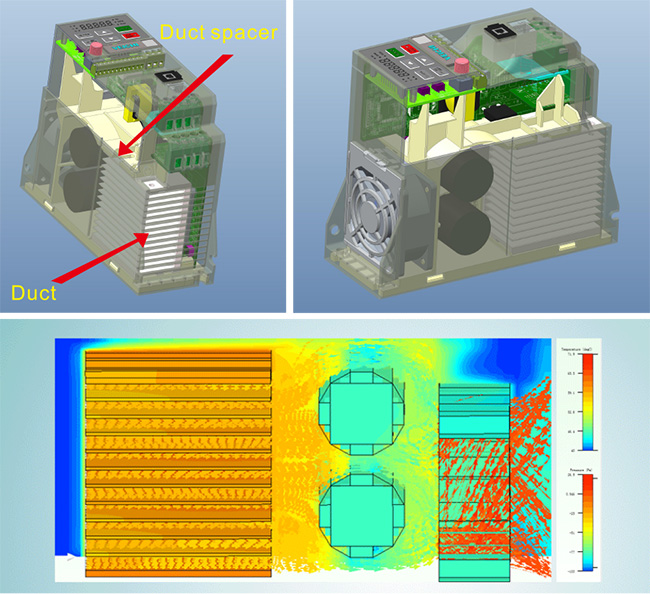

Protective Design

1. High protection: completely independent air duct, scientific layout inside the machine, help the heat dissipation of high-power devices and the dust-proof of the sensing device.

2. High temperature resistance: scientific air duct design, which can quickly dissipate heat, low temperature rise of the machine, and no need of derating at an ambient temperature of 50℃.

GS Series Pump Drive Video

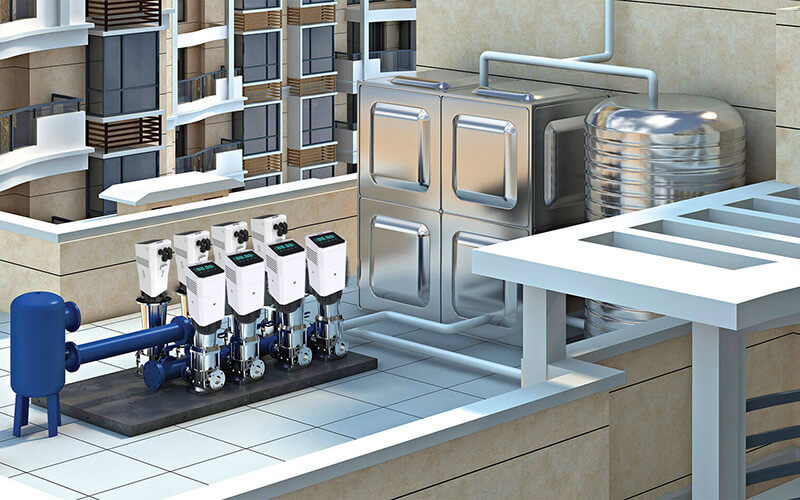

Industrial Applications for GS10 Mini Pump Drive

Applications: Residential water, agricultural irrigation, water conservancy and water affairs, HVAC water treatment.

Specifications

| Voltage, Frequency | Single-phase 220V 50/60Hz; Three-phase 220V 50/60Hz; Three-phase 380V 50/60Hz |

|---|---|

| Allow fluctuations | Voltage imbalance rate: <3%; Frequency: ±5% The distortion rate meets the requirements of IEC61800-2 |

| Closing impulse current | Less than rated current |

| Power factor | ≥0.94 (with DC reactor) |

| Inverter efficiency | ≥96% |

| Output voltage | Output under rated conditions: 3 phases, 0 to input voltage, error less than 5% |

|---|---|

| Output frequency range | 0-600.00Hz |

| Output frequency accuracy | ±0.5% of the maximum frequency value |

| Overload capability | T3 model: 150% rated current for 1 minute, 180% rated current for 5 seconds, 200% rated current for 0.5 second S2 model: 150% rated current 20 seconds, 180% rated current 0.5 seconds |

| Motor type | PMSM, AM |

|---|---|

| Motor control mode | No PG V/F control, no PG vector control |

| Modulation | Optimized space vector PWM modulation |

| Carrier frequency | 1.0~16.0kHz |

| Speed control range | No PG vector control, rated load 1:100 |

| Starting torque | No PG vector control: 150% rated torque at 0.5Hz |

| Torque response | No PG vector control: <20ms |

| Frequency accuracy | Digital setting: Maximum frequency × ± 0.01%; analog setting: Maximum frequency × ± 0.2% |

| Frequency resolution | Digital setting: 0.01Hz; Analog setting: Maximum frequency × 0.05% |

| Torque Control | Torque setting calculation, torque mode speed limit |

|---|---|

| DC braking capability | Starting frequency: 0.00~50.00Hz Braking time: 0.0~60.0s Braking current: 0.0~150.0% rated current |

| Torque boost | Automatic torque increase 0.0%~100.0% Manual torque increase 0.0% ~ 30.0% |

| V/F curve | Four modes: linear torque characteristic curve, self-set V/F curve, torque reduction characteristic curve (1.1 to 2.0 power), square V/F curve |

| Acce. / Dece. curve | Two ways: linear acceleration and deceleration, S curve acceleration and deceleration Four sets of acceleration and deceleration time, the time unit is 0.01s, the longest is 650.00s |

| Rated output voltage | Using the power supply voltage compensation function, the rated voltage of the motor is 100%, which can be set within the range of 50 to 100% (the output cannot exceed the input voltage) |

| Automatic voltage adjustment | Automatically keeps the output voltage constant when the grid voltage fluctuates |

| Automatic energy saving operation | Automatically optimize output voltage according to load under V/F control mode to achieve energy-saving operation |

| Automatic current limiting | Automatically limit current during operation to prevent frequent overcurrent fault trips |

| Instant power down handling | Uninterrupted operation through bus voltage control during instantaneous power loss |

| Standard function | PID control, speed tracking and power-down restart, skip frequency, frequency upper and lower limit control, program operation, multi-step speed, RS485, analog output, frequency pulse output. |

| Frequency setting channel | Keyboard digital setting, keyboard potentiometer, analog voltage/current terminal AI, communication setting and multi-channel terminal selection, main and auxiliary channel combination, can be switched in various ways. |

| Feedback input channel | Keyboard potentiometer, voltage/current terminal AI, communication reference, pulse input X4/PUL |

| Run command channel | Operation panel reference, external terminal reference, communication reference |

| Input command signal | Start, stop, forward and reverse, jog, multi-speed, free stop, reset, acceleration/deceleration time selection, frequency setting channel selection, external fault alarm |

| External output signal | 1 relay output, 1 collector output, 1 AO output can be selected as 0~10V or 4~20mA or 4~20mA output |

| Protective function | Overvoltage, undervoltage, current limiting, overcurrent, overload, electronic thermal relay, overheating, overvoltage stall, data protection, fast protection, input and output phase loss protection. |

|---|

| LCD display | Single line 5-digit display: 1 inverter status quantity display Double line 5-digit digital tube display: 2 inverter status quantity display |

|---|---|

| Parameter copy | Upload and download function code information of the inverter for fast parameter copying |

| Status monitoring | All parameters of the monitoring parameter group such as output frequency, given frequency, output current, input voltage, output voltage, motor speed, PID feedback amount, PID given amount, module temperature, etc. |

| Error alarm | Overvoltage, undervoltage, overcurrent, short circuit, phase loss, overload, overheat, overvoltage stall, current limit, data protection damage, current fault operation, historical fault. |

| Installation place | The altitude is less than 1000 meters, and the derating is more than 1000 meters. The derating is 1% for every 100 meters No condensation, icing, rain, snow, sputum, etc., solar radiation is less than 700W/m2, air pressure 70~106kPa |

|---|---|

| Temperature humidity | -10 ~ +50°C, derating can be used above 40 °C, the maximum temperature is 60 °C (no-load operation) 5% to 95% RH (no condensation) |

| Vibration | At 9 to 200 Hz, 5.9 m/s2 (0.6 g) |

| Storage temperature | -30~+60℃ |

| Installation method | Wall-mounted, closet |

| Protection level | IP20 |

| Cooling method | Forced air cooling |

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message