- Home > Product > Industry-specific Drive > Hydraulic Servo > EHS100 Integrated Hydraulic Servo

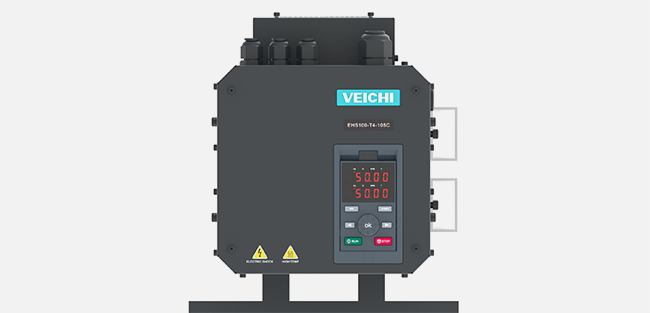

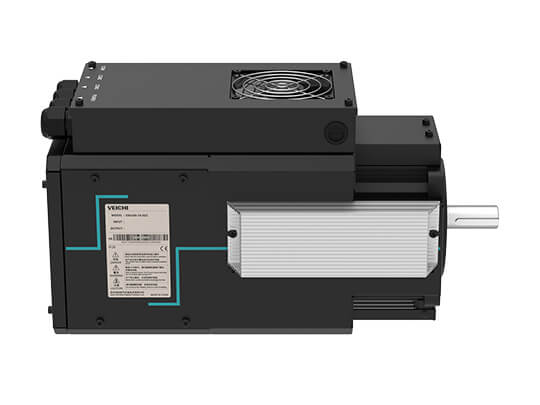

EHS100 Integrated Hydraulic Servo

- Integrated control, power, brake function;

- No need for self-learning, power on;

- Designed for mechanical high frequency vibration;

- Double independent air duct, IP56 fan;

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

EHS100 Integrated Servo Overview

EHS100 is a new generation integrated servo product that combines control, power, and brakes in one. Simplify installation lines, reduce bridges, wire slots, connectors, and line nodes, reduce equipment complexity, increase space utilization, and increase installation efficiency by more than 5 times.

1. Integration: Integrated control, power, and brake functions.

2. No debugging: No need for self-learning, just use it when power on.

3. Anti-vibration: designed for mechanical high-frequency vibration.

4. High protection: double independent air ducts, IP56 fan.

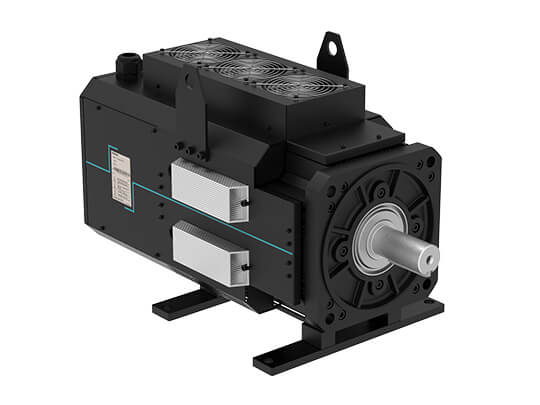

The future has come

A new generation of integrated servo products, combining control, power, and braking into one. Simplify installation lines, reduce bridges, wire slots, connectors, and line nodes, reduce equipment complexity, increase space utilization, and increase installation efficiency by more than 5 times.

Subversion begins

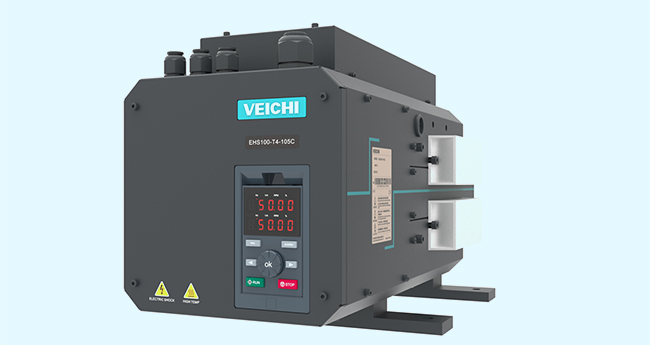

1. Subvert the traditional installation method: There is no need to control the electric cabinet, and the original motor installation method is not changed. It saves space while improving production efficiency, reducing the probability of production errors and the cost of error correction.

2. Less radiation and distributed capacitance: Internal wiring helps improve the EMC electromagnetic compatibility of the system, greatly reduces interference, and ensures the stable operation of the system.

Easy to use

1. The essence of technology is to provide better services: It is not an upgrade process, but an iteration. What changes is not the product, but the thinking.

2. Integrated brake function: The whole system has built-in brakes and brake resistors, eliminating the work of selecting and installing wiring, completely avoiding faults and damage caused by incorrect selection or improper selection of components.

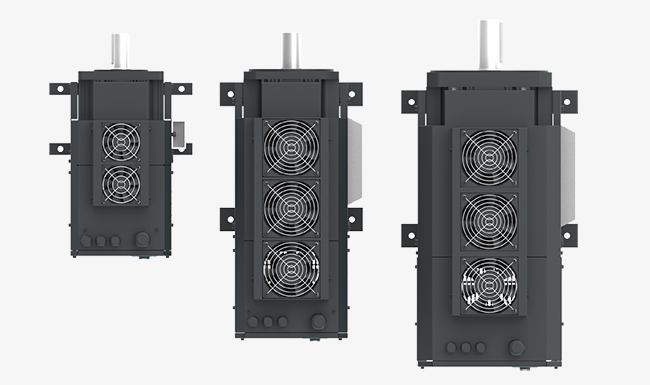

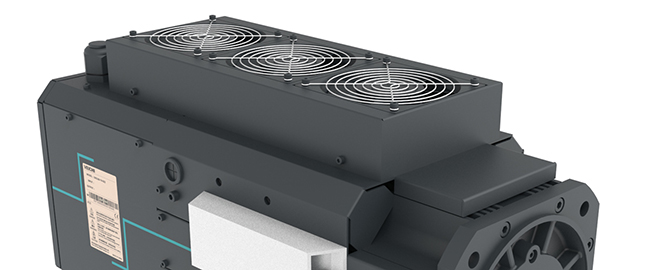

Intelligent temperature control

70,000 hours of the long-life fan (IP65 protection), combined with multi-point temperature detection, intelligent control of fan operation, low load, and long standby conditions are particularly obvious.

New experience

1. AC300V-AC450V wide power input: The ultra-wide AC input voltage range can calmly deal with various grid environments and improve the equipment's adaptability under extreme working conditions.

2. IPM permanent magnet synchronous power design: IPM built-in magnetic steel design, low-temperature rise, fast response.

3. Strong overload: The weak magnetic algorithm, more than 2 times the torque, can easily cope with overload and overspeed conditions.

Powerful kernel

1. Multi-unit control: Multiple joint control modes such as synchronization, follow, superimpose, and intelligent tracking are available.

2. Multiple signals are given: Analog quantity, communication, internal, terminal multi-speed.

3. The movable keyboard can be extended, can be installed independently: The keyboard adopts an RJ45 network cable interface and supports hot-swap. It can be extended long distances and can be installed independently with a bracket.

EHS100 Integrated Servo Video

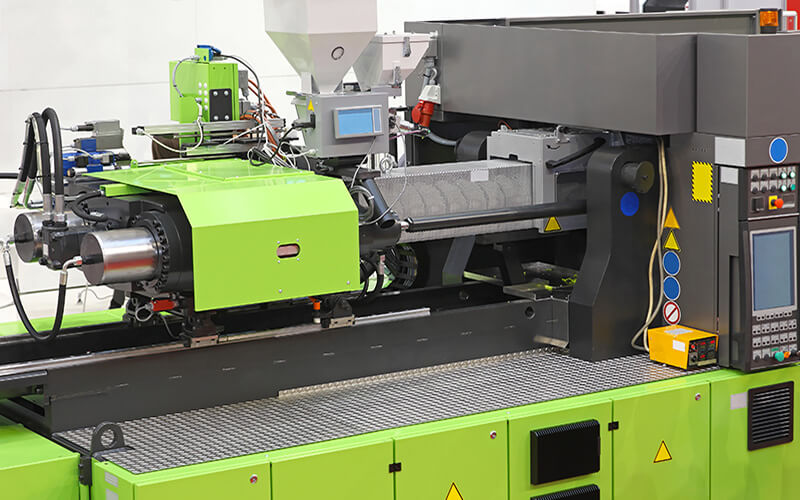

Industrial Applications for EHS100 Integrated Hydraulic Servo

Applications:Injection molding machines, molding machines, die-casting machines, blow molding machines, hydraulic presses, bending machines, etc.

Specifications

| Power range | 4,400 W-35,000 W |

|---|

| Voltage and frequency | Three-phase 380V 50/60HZ |

|---|---|

| Allowable fluctuation range | Voltage: ±15%; frequency fluctuation: ±5% Distortion rate: meet the requirements of IEC 61800-2 |

| Closing impulse current | Less than rated current |

| Drive efficiency | ≥96% |

| Power factor | ≥0.94(With DC reactor) |

| The output voltage | Output under rated conditions: 3-phase, 0~input voltage, error less than 5% |

|---|---|

| Output frequency range | Maximum output frequency: 320HZ |

| Overload capacity | 150% rated current 60s, 180% rated current 5s, maximum 2.5 times |

| Modulation | SVPWM |

| Carrier frequency range | 2.0~8.0kHz(Model determination) |

| Digital setting | maximum speed×±0.01% |

| Analog setting | maximum frequency×±0.2% |

| Speed resolution | Digital setting: 1rpm Analog setting: maximum speed×0.05% |

| Acceleration and deceleration curve | Linear acceleration and deceleration, S curve acceleration and deceleration |

| Automatic energy saving operation | According to the load condition, the output voltage is automatically optimized to realize energy-saving operation |

| Automatic current limit | Automatically limit the current during operation to prevent frequent over-current fault trips |

| Standard function | Oil pressure closed loop control, speed control, RS485, analog output |

| Speed setting channel | Keyboard digital setting, analog voltage/current terminal AI1, analog voltage/current terminal AI2, analog voltage/current terminal P-AI, communication setting and multi-channel terminal selection, combination of main and auxiliary channels. |

| Feedback input channel | Voltage/current terminal AI1, voltage/current terminal AI2, voltage/current terminal P-AI, communication setting |

| Run command channel | Operation panel setting, external terminal setting, communication setting |

| Input command signal | Start, stop, forward and reverse rotation, jog, multi-speed, free stop, reset, acceleration and deceleration time selection, speed setting channel selection, external fault alarm |

| External output signal | 2 relay outputs; 1 transistor output; 2 analog outputs, voltage output range: 0~10V/0~10V, current output range: 0~20mA/0~20mA |

| Protective function | Overvoltage, undervoltage, current limit, overcurrent, overload, overheating, data protection |

|---|

| LED display | Single line 5-digit digital tube display: Can monitor 1 status |

|---|---|

| Status monitoring | Pressure command, pressure feedback, speed setting, speed feedback, flow command, output current, output voltage, output torque, output power, bus voltage, module temperature, motor temperature, input terminal X connected state, output terminal Y connected Status etc. |

| Error alarm | Self-learning abnormality, sensor feedback disconnection, motor overheating, driver overheating, encoder failure, communication failure, overvoltage, undervoltage, overcurrent, short circuit,Phase loss, overload, stall, current limit, data protection damaged, current fault operating status, historical fault. |

| Installation site | Indoor, the altitude is not more than 1000m, no corrosive gas and direct sunlight |

|---|---|

| Temperature and humidity | From -10°C to +40°C 20%—95%RH(No condensation) |

| vibration | Less than 0.5g |

| Storage temperature | From -25℃ to +60℃ |

| Installation method | Wall-mounted, vertical cabinet |

| Protection level | IP20 |

| Cooling method | Forced air cooling, liquid cooling |

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message