- Home > Product > Industry-specific Drive > Tension Control > AC200T Special Inverter for Tension Control

AC200T Special Inverter for Tension Control

- Advanced torque identification algorithm that could realize high output torque accuracy and low torque ripple

- Intelligent roll diameter recognition could achieve high recognition accuracy and strong anti-disturbance ability

- Resilient to retractable reel diameter & smooth start, stable tension at high and low speeds

- Professional friction compensation module ensures consistent front and back tension during material processing

Features

- Features

- Specifications

- Downloads

- Solutions

- Cases

- News

- Related Products

- Additional Information

AC200T Special Inverter for Tension Control Overview

AC200-T special frequency converter for tension control keeps the tension constant by controlling the output torque and automatically calculating the roll diameter. No need to install a tension sensor, no need for external feedback signal of current position or current tension. In most applications, it is not even necessary to install a speed feedback encoder to accurately provide constant tension and ensure that the thickness or thickness of the processed material is uniform.

1. Using the torque recognition algorithm, the output torque has high precision and small torque ripple.

2. Adopt intelligent roll diameter recognition, with high recognition accuracy and strong anti-disturbance ability.

3. It has strong adaptability to the diameter of rewinding and unwinding reel, smooth starting, and stable tension at high and low speeds.

4. The built-in professional friction compensation module fundamentally ensures that the tension control characteristics of the front and back tension are consistent during material processing.

Rich functions and excellent performance

1. Friction compensation, the tension-specific inverter has dynamic and static friction compensation for the mechanical system, which can optimize the control effect of tension and improve the stability and response speed of the tension system.

2. Zero-speed tension, the special frequency converter for tension can provide the tension value that can be automatically identified and set for the on-site zero-speed state to ensure that the on-site operation and zero-speed require different tension.

3. Other functions, stop and brake signal output, material break detection, rewind/unwind frequency limit, etc.

Tension special function

1. Taper coefficient, tension-specific inverters are aimed at the occasions where the tension decreases with the increase of the coil diameter. The taper coefficient can be set to realize the flatness of the winding to achieve better forming effects.

2. Automatic roll change, the tension-specific inverter has a wealth of automatic roll change functions, which can realize automatic roll change without stopping at high speed, which greatly improves production efficiency.

Multiple roll diameter calculation methods

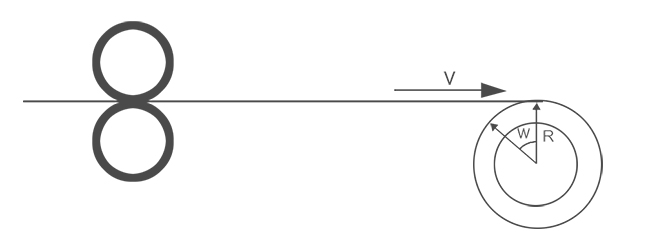

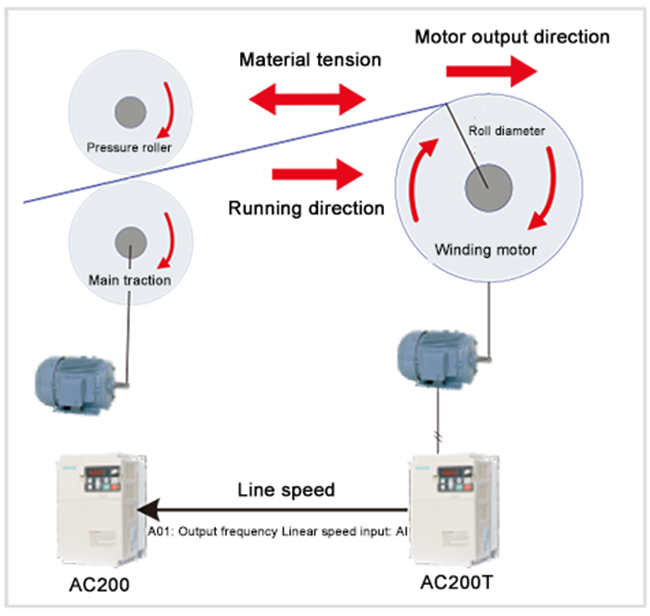

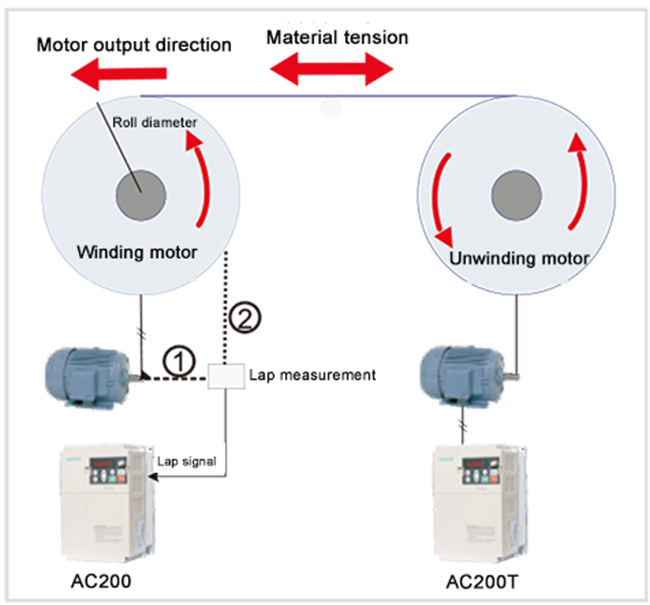

The V in the upper head represents the linear velocity of the traction, W represents the angular velocity of the winding reel, R represents the winding radius, and D represents the winding diameter.

Linear velocity method

AC200T tension control special frequency converter can obtain accurate winding diameter through the linear speed of the previous stage, its own angular speed, and the mechanical speed ratio.

Thickness integral method

According to the thickness of the material, the number of rotations of the installation reel is accumulated to obtain the material reel diameter. AC200T tension control special frequency converter accumulates the number of turns of the reel through the encoder, to obtain the diameter of the winding, without adding external proximity switches and several turns of devices.

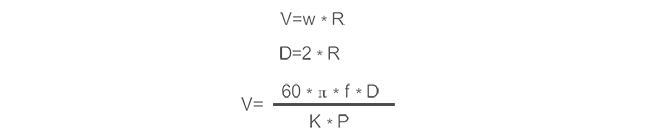

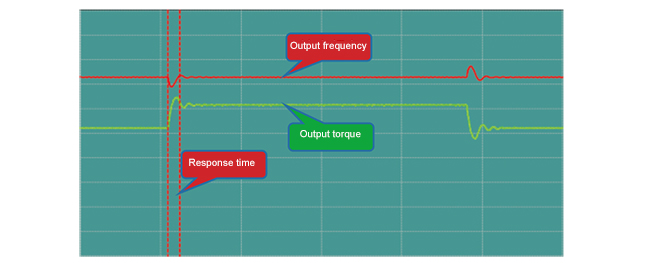

Speed torque response fast

Speed rigidity: Sudden 100% load and sudden unload at 40Hz, the recovery time is within 10ms.

Torque response: The load is not mechanically locked. The AC200T given torque is suddenly increased from 0% to 100% and suddenly reduced from 100% to 0%, and the torque response time is within 10ms.

Industry electrical system solutions

Linear speed method application: the front-end machinery provides material traction to determine the material linear speed, and the material tension is determined by AC200T winding. The coil diameter can be calculated by the given linear speed of the traction.

Thickness method application: The front end machine does not provide a traction mechanism to determine the line speed, the material line speed is directly determined by the front motor, and the material tension is determined by the AC200T winding. The winding diameter of this scheme can be calculated by the lap counting pulse provided by the encoder, or an external lap counting device can be added.

Industrial Applications for AC200T Special Inverter for Tension Control

Applications:Industrial production requires strip or wire to maintain constant tension.

Specifications

| Power range | 400 W-630,000 W |

|---|

| Voltage and frequency | Single-phase 220V 50/60Hz Three-phase 380V 50/60Hz; Three-phase 220V 50/60Hz Three-phase 660V 50/60Hz Three phase1140V 50/60Hz |

|---|---|

| Allow fluctuations | Voltage imbalance rate: <3%; Frequency: ±5%; Distortion rate meets IEC61800-2 requirements |

| Closing surge current | Less than rated current |

| Power factor | ≥0.94(With DC reactor) |

| Inverter efficiency | ≥96% |

| The output voltage | Output under rated conditions: 3-phase, 0~input voltage, error less than 5% |

|---|---|

| Output frequency range | Type G: 0~600Hz |

| Output frequency accuracy | ±0.5% of maximum frequency value |

| Overload capacity | Type G: 150% rated current for 1 minute, 180% rated current for 10 seconds, 200% rated current for 0.5 seconds |

| Motor control mode | V/F control without PG, vector control without PG, V/F control with PG, vector control with PG |

|---|---|

| Modulation | Optimize space vector PWM modulation |

| Carrier frequency | 0.7~16.0kHz |

| Speed control range | Vector control without PG, rated load 1:100; vector control with PG, rated load 1:1000 |

| Steady-state speed accuracy | Vector control without PG: ≤2% of rated synchronous speed; vector control with PG: ≤0.05% of rated synchronous speed |

| Starting torque | Vector control without PG: 150% rated torque at 0.5Hz; Vector control with PG: 200% rated torque at 0Hz |

| Torque response | Vector control without PG: <20ms; Vector control with PG: <10ms |

| Frequency accuracy | Digital setting: maximum frequency×±0.01%; analog setting: maximum frequency×±0.2% |

| Frequency resolution | Digital setting: 0.01Hz; Analog setting: maximum frequency×0.05% |

| DC braking capability | Starting frequency: 0.00~50.00Hz; Braking time: 0.0~60.0s; Braking current: 0.0~150.0% of rated current |

|---|---|

| Torque boost | Automatic torque increase 0.0%~100.0%; manual torque increase 0.0%~30.0% |

| V/F curve | Four methods: linear torque characteristic curve, self-set V/F curve, reduced torque characteristic curve (1.1~2.0 power), square V/F curve |

| Acceleration and deceleration curve | Two ways: linear acceleration and deceleration, S curve acceleration and deceleration Four sets of acceleration and deceleration time, the time unit is 0.01s, the longest is 650.00s |

| Rated output voltage | Using the power supply voltage compensation function, the rated motor voltage is 100%, which can be set in the range of 50 to 100% (the output cannot exceed the input voltage) |

| Automatic voltage adjustment | When the grid voltage fluctuates, it can automatically keep the output voltage constant |

| Automatic energy saving operation | Under V/F control mode, the output voltage is automatically optimized according to the load to realize energy-saving operation |

| Automatic current limit | Automatically limit the current during operation to prevent frequent over-current fault trips |

| Instantaneous power failure processing | In case of instantaneous power failure, uninterrupted operation is realized through bus voltage control |

| Standard function | PID control, speed tracking and restart after power failure, jump frequency, frequency upper and lower limit control, program operation, multi-speed, RS485, analog output, frequency pulse output |

| Frequency setting channel | Keyboard digital setting, keyboard potentiometer, analog voltage terminal VS, analog voltage/current terminal AI, analog current terminal AS, communication setting and multi-channel terminal selection, main and auxiliary channel combination, expansion card, can be switched in various ways. |

| Feedback input channel | Voltage terminal VS, voltage/current terminal AI, current terminal AS, communication setting, pulse input PUL |

| Run command channel | Button key setting, communication setting |

| Input command signal | Start, stop, forward and reverse rotation, jog, multi-speed, free stop, reset, acceleration and deceleration time selection, frequency setting channel selection, external fault alarm |

| External output signal | 2 relay outputs, 1 collector output, 1 AO output can be selected as 0~10V or 4~20mA output, 1 AO output can be selected as 0~10V or 4~20mA or frequency pulse output output |

| Protective function | Overvoltage, undervoltage, current limit, overcurrent, overload, electronic thermal relay, overheating, overvoltage stall, data protection, fast protection, input and output phase loss protection |

|---|

| LED display | Single line 5-digit digital tube display: It can monitor 1 inverter status Dual-line 5-digit digital tube display: It can monitor the status of 2 inverters |

|---|---|

| Parameter copy | The function code information of the inverter can be uploaded and downloaded to realize fast parameter copy |

| Status monitoring | All parameters of the monitoring parameter group such as output frequency, given frequency, output current, input voltage, output voltage, motor speed, PID feedback quantity, PID given quantity, module temperature, etc. |

| Error alarm | Overvoltage, undervoltage, overcurrent, short circuit, phase loss, overload, overheating, overvoltage stall, current limit, data protection damaged, current fault operating status, historical fault. |

| Installation site | If the altitude is lower than 1000 meters, derating for use above 1000 meters, derating by 1% for every 100 meters No condensation, icing, rain, snow, hail, etc., solar radiation less than 700W/m2, pressure 70~106kPa |

|---|---|

| Temperature and humidity | from -10℃ to +50℃, derating can be used above 40℃, the maximum temperature is 60℃ (no-load operation) 5% ~ 95%RH(No condensation) |

| vibration | When 9~200Hz,5.9m/s2(0.6g) |

| Storage temperature | From -30℃ to +60℃ |

| Installation method | Wall-mounted, vertical cabinet |

| Protection level | IP20 |

| Cooling method | Forced air cooling |

Downloads

| File Name | Type | Language | File Type | Update | Download |

|---|

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message