"Hi Will! Can you tell me the structural characteristics of the company's products?"

"Of course, no problem!"

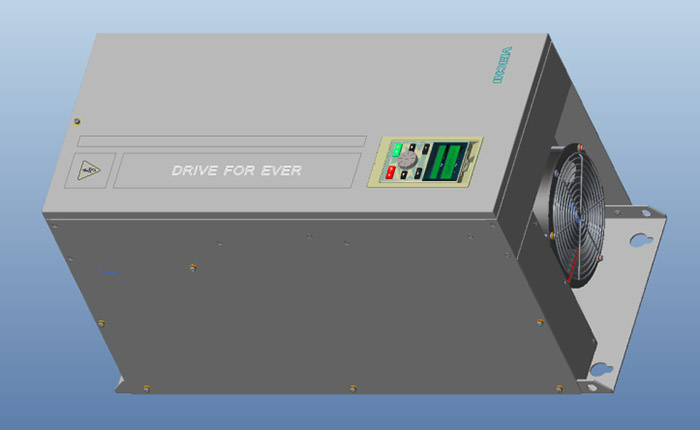

Let's take a look at these prototypes, such as the company's flagship new generation product, the AC300 series book-type narrow-body inverter.

The AC300 series book-type narrow-body inverter

The whole system adopts a narrow body design

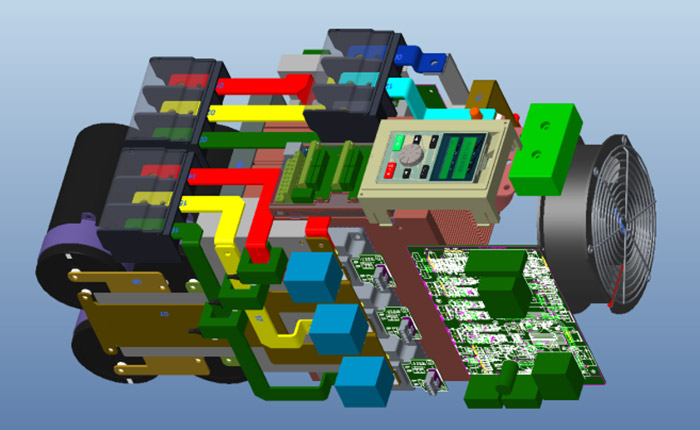

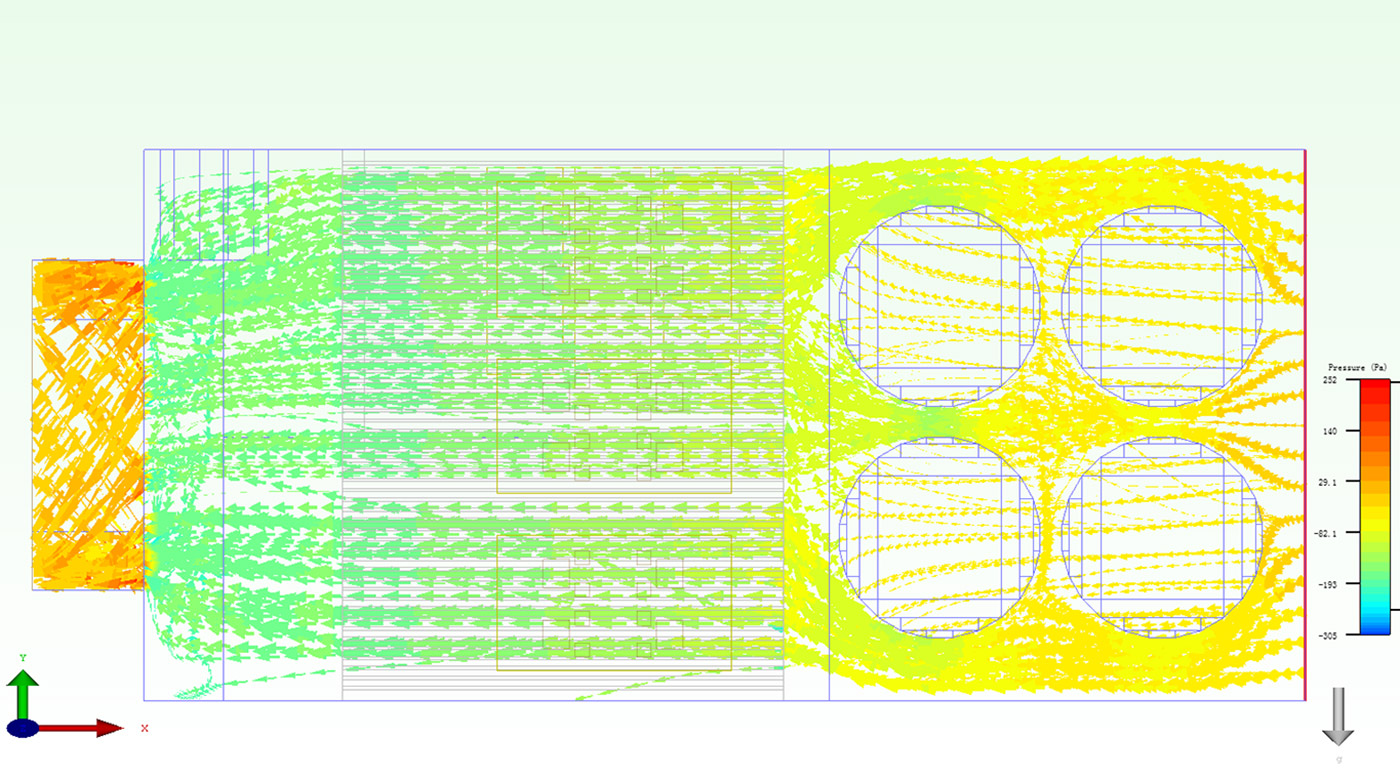

This is a highly competitive product. The whole system adopts a narrow body design, which breaks the planar layout thinking of the previous generation inverter, creatively proposes a full three-dimensional system structure and air duct mode, and the effective utilization of space has been raised to a new height. Compared with the previous generation product, the designed product is about 30~60% smaller than the power volume. At the same time of higher power density, it effectively solves the problem of product temperature rise caused by high power density. The distribution of components in the cavity is more reasonable, the cooling air duct is effectively isolated from the electrical cavity, and at the same time, the protection problem of the product in a high dust pollution environment is realized.

The narrow body structure is more suitable for the current market environment. For example, the small and medium power sections are mainly for cabinet installation and wall mounting. The volume advantage of the narrow body design makes the customer's secondary power distribution easier. Greatly reduced equipment investment costs, including site, number of cabinets, wiring, power supply and distribution costs, etc.

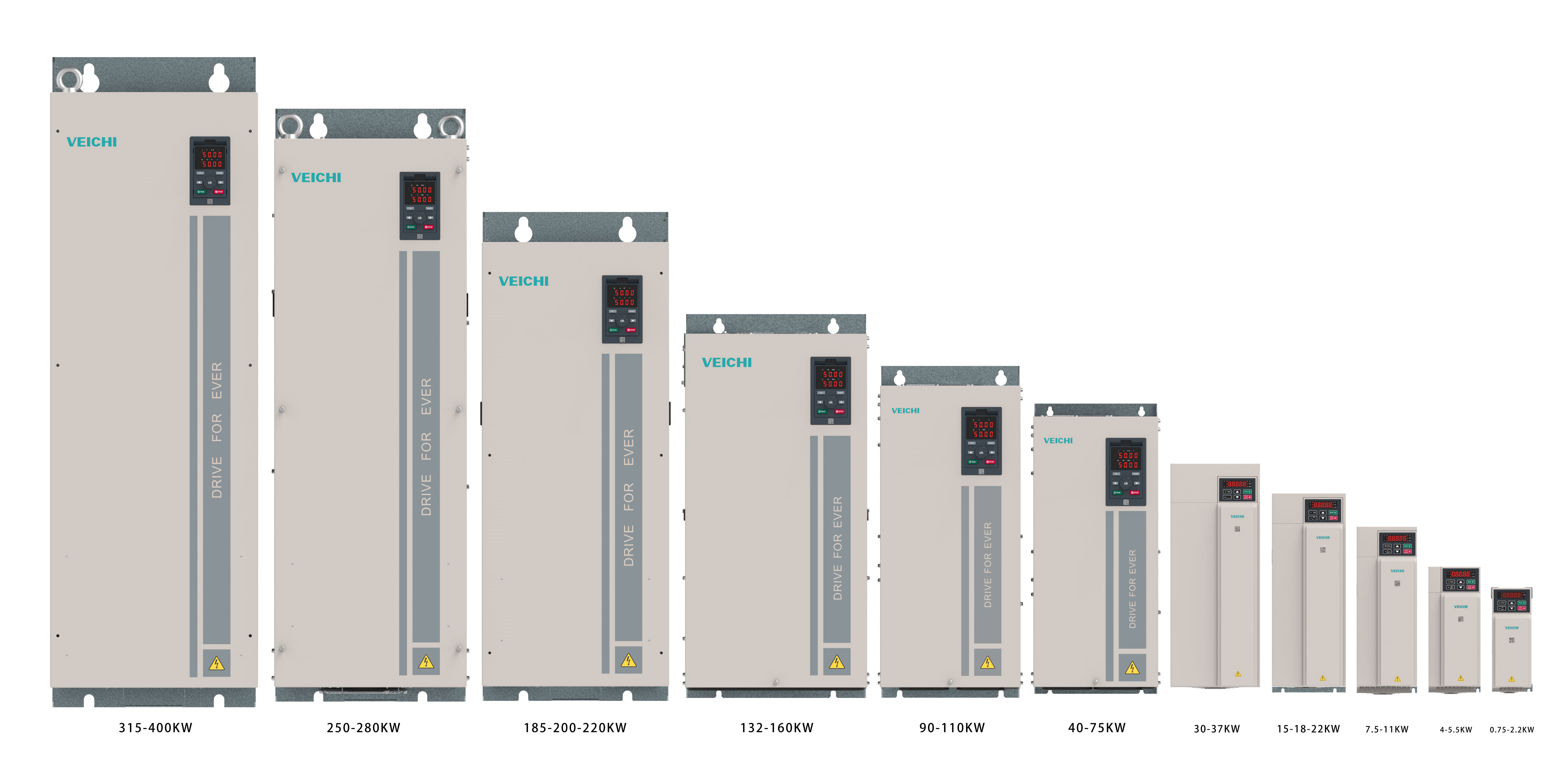

AC300 series inverter

Therefore, the highlights in the above product forms highlight the importance of one of the core R & D departments-the structural department. As the chief designer team responsible for the design and implementation of all product forms of the company, its importance is evident.

In similar project development cases, structural engineers are responsible for the main tasks including:

1. System layout at the product solution stage.

2. Chassis design, how to achieve a wide variety of device installation cheapness, shock resistance, interference between devices and shielding. Sheet metal shell processability, plastic shell and die-casting structure mold manufacturability. Also drawing Accuracy, closed-loop and feasibility of assembly dimensional chain.

3. Appearance modeling, combining internal structure and functional characteristics, beautiful and elegant design.

4. Installation method, how to best match the customer environment on-site, realize quick installation, quick maintenance and enhance customer experience.

5. Wiring design, how to design the routing path, and fixed cable management must consider aesthetics and facilitate production operations, as well as the mutual interference between strong and weak current.

6. Packaging and transportation, how to design packaging materials, including inner cushions, cardboard boxes, wooden boxes, etc., a variety of structural forms. Both aesthetics and cost savings must be considered, while transportation reliability and standard requirements must be met.

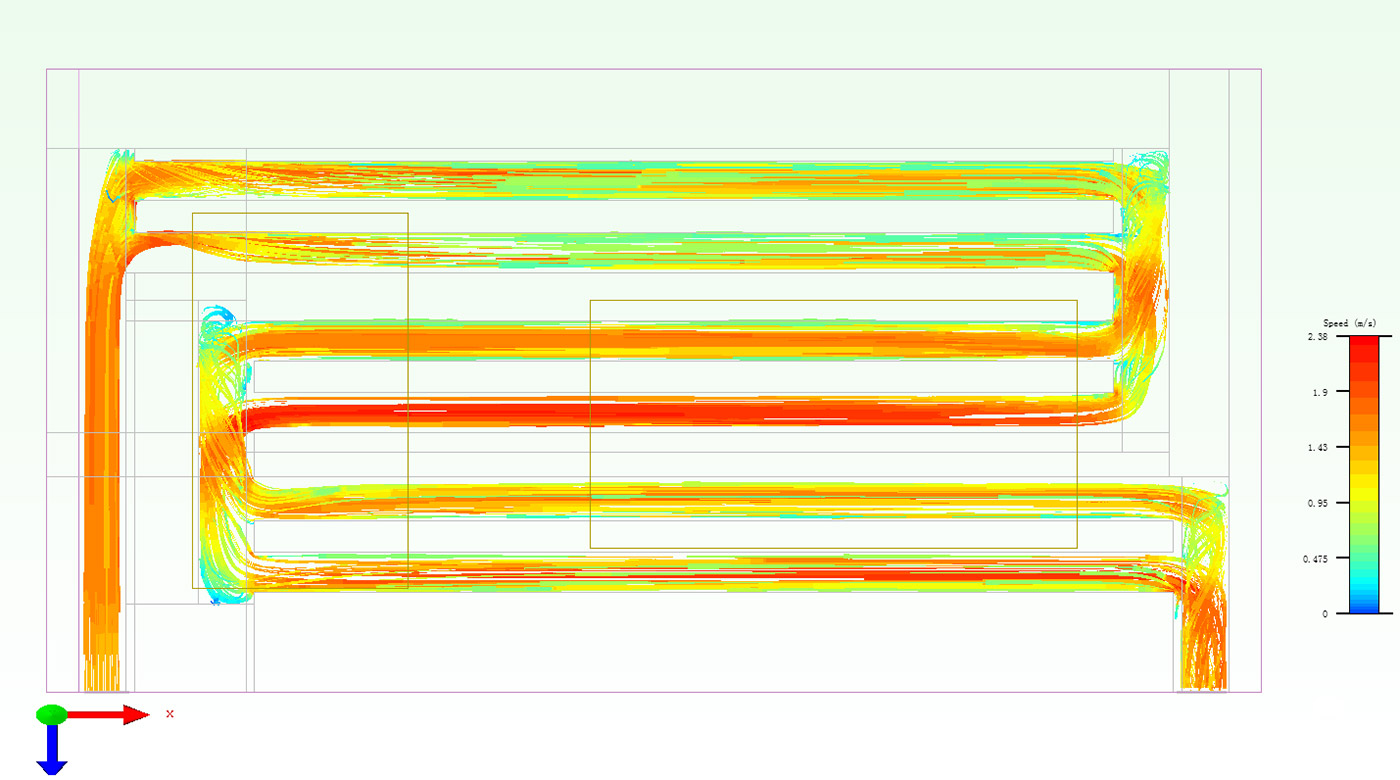

Water cooling radiator runner simulation effect

Air cooling system air flow simulation effect

The following tower crane integrated control product is a control cabinet that can be directly used outdoors. So what's so special about outdoor products?

Tower crane integrated control product

First of all, outdoor products are subject to prolonged wind and rain, so the protective performance (waterproof and dustproof) of the cabinet will be particularly high. In simple terms, it is to withstand the storms!

Tower crane product is to withstand the storms

In addition, outdoor products also need to strengthen their resistance to ultraviolet rays, such as the outer coating of cabinets, external cables, etc., which need to be resistant to aging, abrasion and scratches, and external connectors need special waterproof structures. In addition, this cabinet solves a very practical technical problem.

Due to the compact installation space of the cabinet, it needs to be designed as a double door structure. However, the traditional double-door structure is almost the same with an intermediate vertical beam installed in the middle of the cabinet, or the interior of the cabinet is divided into two to form a combination of two cabinets to prevent water from entering the middle position when the two doors are closed. However, such a structure has a defect, that is, the waste of space in the position of the vertical beam and prevents the installation and maintenance of the device in that position.

This type of waterproof door cabinet from VEICHI broke this traditional structural thinking. In the single-width cabinet door, the middle vertical beam is eliminated, and the "blocking" and "sparse" methods are used to perfectly realize the reliability of waterproofing. At the same time, the cabinet space is released to the maximum, and the cabinet itself is highly manufacturable, and the overall cost is significantly reduced.

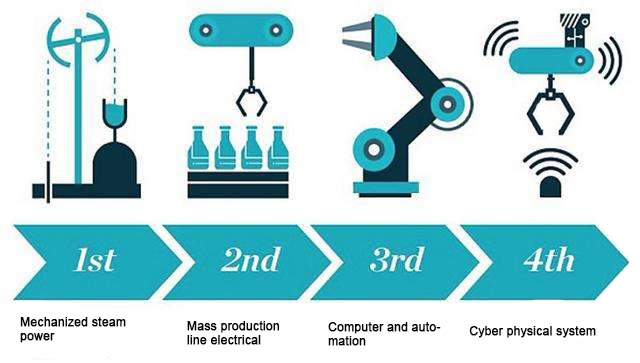

Therefore, the structural engineer is a versatile person with a wide range of knowledge. It involves environment, materials, machinery, system design, graphic design, shape design, thermal design, wiring design, packaging design, material processing, quality inspection, process manufacturing, safety regulations and Reliability, etc. Across disciplines such as mechanical, material, thermal, structural mechanics, ergonomics, power supply and distribution.

Mechanical structural engineers came along with the industrial revolution and distributed to various fields of automation.

Industrial revolution

Therefore, it is not easy to be an excellent structural engineer. You must have a broad knowledge and strong basic skills. Every development of a high-quality product requires the endurance and courage to sharpen a sword for ten years. The structural engineers of VEICHI will continue to work hard and innovate, and are committed to becoming a first-class enterprise in the field of electrical transmission and industrial control!

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message