- Home

- Industry News

- Motion controller + servo of VEICHI application

Introduction to label inspection machine

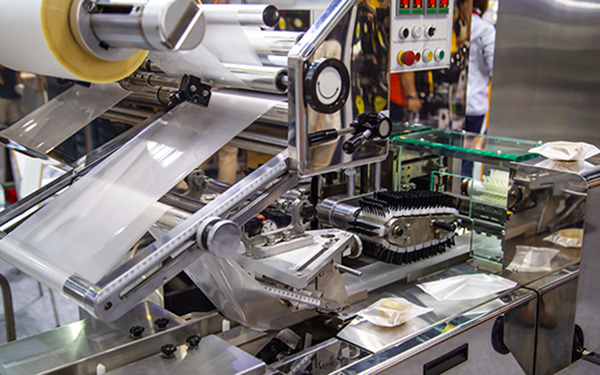

With the development of the times, there are labels for various uses and shapes in life. Ordinary coated papers are processed into printed labels, coated, die-cut, etc., and are made into finished labels. However, it is impossible to ensure that all the links are free of problems during the production process, so the quality of the finished product label is also required to be tested.

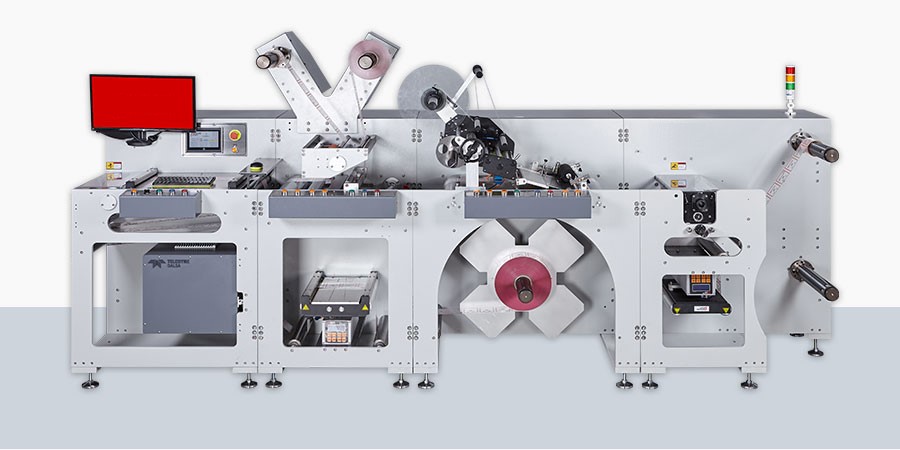

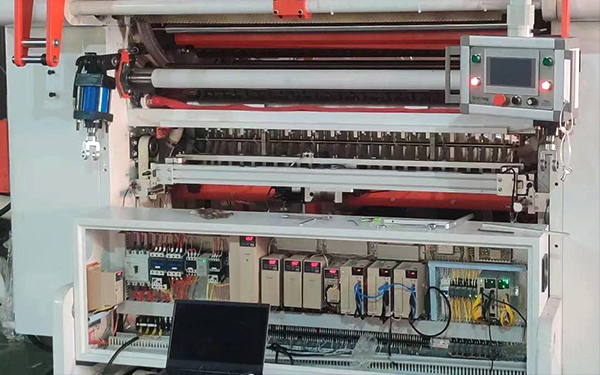

The label inspection machine is also called the label rewinding machine (as shown in the figure below). Usually, a quality inspection machine mainly consists of: unwinding part, rectification, detection system, slitting mechanism, and winding up and down. While detecting the quality of the label, it is also possible to complete the striping and rewinding work.

The label inspection machine

System introduction

This set of systems uses VEICHI high-performance PLC, V5 as the controller, select SD700 series high-performance servo of VEICHI as the power mechanism, VI10-070D touch screen as the human-computer interaction interface. The controller comes with ModbusTCP network port communication, and data interaction with the detection system host computer.

The system runs stably, the maximum speed can reach 300m/min, the winding diameter calculation is stable, the calculation error is ±3mm, the torque control is stable, and the material has no jitter during any speed switching or acceleration/deceleration process. The label stop accuracy is less than 5mm, and the production calculation accuracy is ±1 sheet.

System solutions

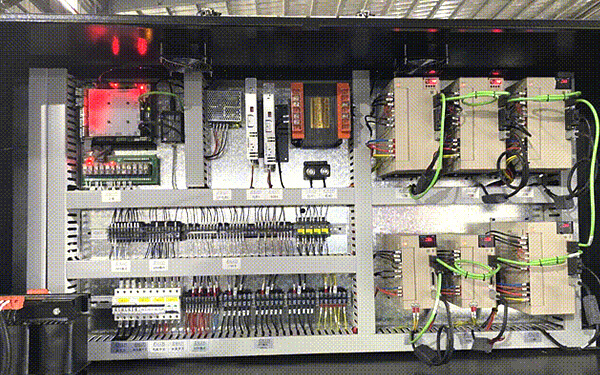

1. The VEICHI product and hardware components applied to the system are shown below.

The VEICHI product and hardware components applied to the system

2. Solution realization

1) The VEICHI high-performance motion controller V5-MC104 is selected as the upper control, and the traction servo and the strip servo are controlled by the pulse output. The torque control of the rewinding and unwinding servo is performed by RS485 communication.

2) The V5 controller interacts with the detection system using modbusTCP communication. The main interactive content has start-stop control, line number transmission, and command transmission.

3) The V5 controller and the touch screen communicate using RS422, and the user adjusts and views various parameters in real time on the touch screen.

System advantage

1. The whole machine adopts the V5 motion controller of VEICHI with a unique 6-axis high-speed design. The highest output pulse frequency is 3MHZ, which meets the ultra-high pulse frequency control. IO uses plug-in terminal blocks for easier wiring and cleaner wiring. It has a standard shaft connection with the servo, eliminating the need for additional wire bonding, saving time and effort.

2. All operating parameters of the HMI human-machine interface are centrally controlled and the performance is stable. The interface can realize language switching, arrears lock, secret interface and other functions.

3. The servo torque is controlled by RS485, and the solution is more economical.

4. The coil diameter calculation is stable, and the calculated value fluctuation can be controlled at ±3 mm.

5. The torque control is stable. Under any speed and acceleration and deceleration, the material has no jitter, and the camera adopts normal black lines.

6. The production calculation is accurate, and the error between the real-time production value and the set production value after shutdown is ±1.

7. When testing, the defective label can be stopped accurately, and the shutdown accuracy is within 5mm.

8. Reserve a variety of host computer docking interfaces.

Summary

The VEICHI product inspection system has the advantages of high efficiency and high stability. The system solution is simpler and more economical, and the hardware wiring saves time and effort. The system is easy to operate, and the parameters are easy to understand and easy to adjust.

The stripe supports up to 300m/min, and the system is stable at the highest speed. There is no abnormality in the coil diameter calculation. The winding torque control is stable and the material has no jitter. The accuracy of shutdown and the calculation accuracy of production output are stable and stable, and are not affected by speed.

The system is highly open, and the user can adjust the system parameters and system switches according to different requirements and working conditions to ensure stable operation of the system and meet operational requirements.

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Leave a Message

Leave a Message